Description

DPY351 Controller

Monitor, Configure & Manage Adelsystem Devices

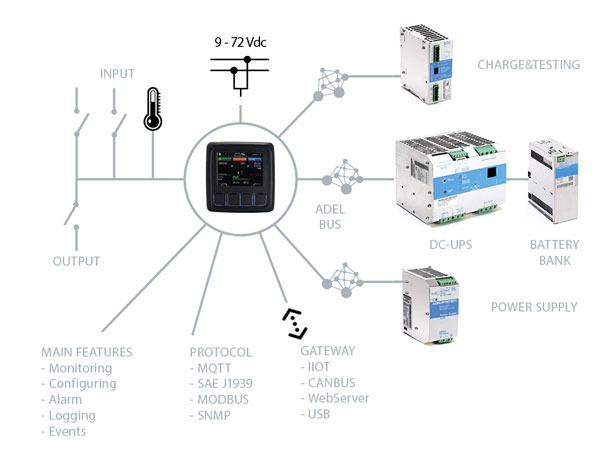

DPY351 is a robust and versatile multifunction display that allows monitoring, configuring and managing the ADELSystem devices connected in an ADELBus network. DPY351 was developed to connect to all the new devices developed by ADELSystem. Through ADELBus (CANBus and ModBus) it is possible to establish the connection of configuration, reading, evolution of the device data. Through the DPY351 it is possible to create Events, they are the result of an algorithm established by the DPY351 among the various interconnected devices.

Monitoring

It is possible the monitoring of the input and output data, peak current, peak voltage, all the battery parameters such as temperature, State of Charge internal Impendency

Configuration

With the DPY351, it is possible to modify the parameters of any ADELsystem device connected: DC Ups, Power Supply and Battery Charger.

Alarms Management

All the alarms present on the single device are immediately reported.

History

The history parameters are recorded inside each device. The DPY351 allows inspection of all historical parameters of each single device.

Gateway & Protocols

- Web Server HTTP for Configuration and Driver the device by Ethernet; static or Dynamic IP

- Modbus TCP/IP Configuration TCP/IP Configuration group of parameter default values. They allow unique identification of the unit in the network.

- SNMP v2c An ADELsystem MIB table is provided which consists of a list of parameters of the connected power device that can be remotely read, or read-written through the SNMP. Each parameter, (OID), is mapped one-toone to a Modbus RTU holding register

- MQTT communication allows the DPY351 to connect to the ADELView System Cloud for the remote monitoring of the power devices connected to the DPY using Modbus or CANbus

Products Compatible with DPY351

CBI2420A 24V DIN Rail DC UPS 500W

CBI4810A 48V DIN Rail DC UPS 500W

CBI1235A 12V DIN Rail DC UPS 420W

CBI2801224A 12V & 24V DIN Rail DC UPS 180W/240W