The General Project

Helios manufactured a rectifier module in the same physical format as the original 19” modules, facilitating plug-in replacement of the existing modules, retaining existing Nortel frames and site infrastructure.

The aim of this approach was the ability to provide the customer with zero downtime during the replacement of the system, thus significantly reducing the cost and the risks of completely powering down the major IT infrastructure. Anyone in the industry is very well aware that once you power down equipment that runs 24/7 for years, and let it cool down, you can expect with a high degree of certainty that a portion of the equipment will not power back up.

This design required comprehensive and detailed engineering. In the electrical sense (to enable parallel operation of the old and new rectifiers during the exchange process) and as much in the mechanical part to ensure physical fit inside the frames and at the same time ensure precise mating of the bus bars making electrical connections sound which is critical for safe and reliable long-term operation.

Key Facts

- End customer: TPG – Internet Service Provider (NBN, FTTB & Mobile)

- Location: Queensland, Australia

- Solution: 75kW modular rectifier system with remote monitoring via Ethernet

Features

- N+1 redunancy.

- Identical form factor to legacy system being replaced.

- Identical output terminals and connectors.

- Remote monitoring via Ethernet, replacing older analogue monitoring.

Customer's Requirement

To replace the 48V Nortel 19” modular rectifier system in a major Brisbane data centre.

Equipment was 25 years old and had reached the end of its life cycle. There were no available spare parts (recycling the components from other decommissioned replaced locations) and concerns about reliability in general due to the age of the equipment.

Customer's Challenge

The Field Operations & Data Centre team decided to go ahead with a replacement legacy DC Power System which was not longer serviced by the original supplier.

Features Required

- Redundant DC Power System with the same form factor and with BUS bars, circuit breakers and alarms in the same position

- Changeover with minimum downtime, it means at any stage 54V and 600A of current must be kept flowing through the system

Helios' Solution

Helios manufactured a rectifier module in the same physical format as the original 19” modules, facilitating plug-in replacement of the existing modules, retaining existing Nortel frames and site infrastructure.

The aim of this approach was the ability to provide the customer with zero downtime during the replacement of the system, thus significantly reducing the cost and the risks of completely powering down the major IT infrastructure. Anyone in the industry is very well aware that once you power down equipment that runs 24/7 for years, and let it cool down, you can expect with a high degree of certainty that a portion of the equipment will not power back up.

This design required comprehensive and detailed engineering. In the electrical sense (to enable parallel operation of the old and new rectifiers during the exchange process) and as much in the mechanical part to ensure physical fit inside the frames and at the same time ensure precise mating of the bus bars making electrical connections sound which is critical for safe and reliable long-term operation.

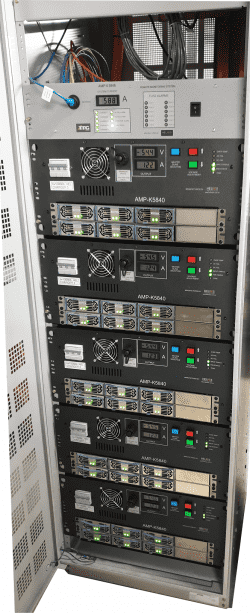

AMP-K5840 & AMP-K5848

AMP-K5840: Battery charger system made up of six units HFE2500-48 units in a custom-made enclosure to provide 15kW of output power. Five AMP-K5840 are connected in parallel, achieving a total of 75kW. Helios design included an additional level of modularity, as each 19” module had internally six of 2.5kW pluggable sub-modules, providing N+1 redundancy on 19” module-level (12.5kW capacity vs 10kW of the original 19” module).

AMP-K5848: Remote monitoring unit used to monitor and control the 75kW Battery Charger System. The remote monitoring unit is mounted in a 3U 21″ rack case and uses TCP/IP network communication protocol.

Core Product Integrated Into The AMP-K5840

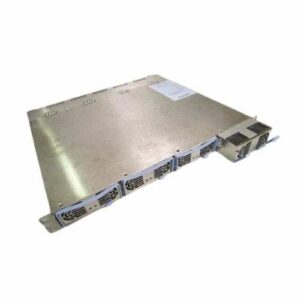

Our design department chose the TDK-Lambda* HFE2500-48 1U DC Power Supply which is one of the most reliable rectifier systems within our range of 1U modular DC Power Systems.

Key Factors For Selecting HFE2500-48 DC Power Supply

- High power density (up to 10kW in 1U rack)

- Hot-swap front end

- Internal ORing MOSFET & Current Share between modules

- Climate Savers Computing efficiency standards

- Isolation diodes for N+1 Redundancy